ABOUT US

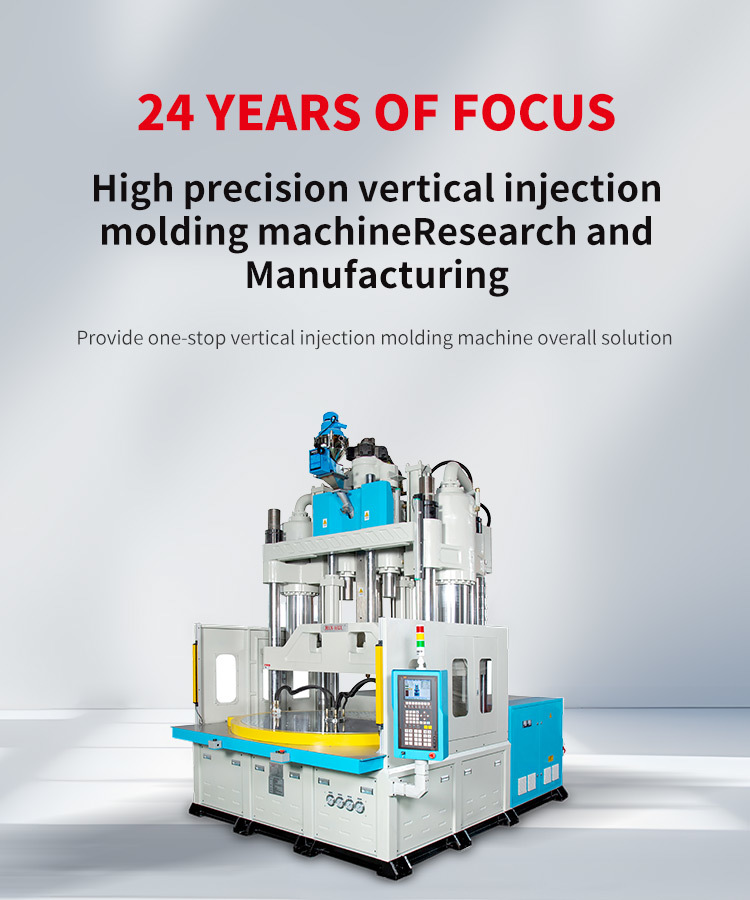

Guangdong MIN-HUI Intelligent Equipment Co., Ltd.is a joint venture specializing in the manufacture of vertical injection molding machines. It has accumulated more than 21 years of experience in R&D and manufacturing of injection molding machines. Provide advanced and precise injection molding equipment for related industries. The electrical and hydraulic parts are made of famous brand products from Japan and Taiwan. The well-made Minghui machinery pursues "safety, speed, stability and durability". The uniquely designed zero-pressure and slow-speed mold closing technology protects personal safety and molds. Quality, technology and service rank first in the industry.

Founded in

Company Staff

Annual Production

Annual total value

Product Center

MIN-HUI · Customization and Technological Advantages

Free Proposal

Free Trial Mold

Free On-site Training

Precise

Shooting Accuracy 0.02mm

Servo Valve or Electric Injection System

Energy Conservation

Shooting Accuracy 0.02mm

Return on Investment within 6-12 months

Security

35000 households

The customer has no security issues

Durable

30-year service life

Automation

Can be paired with a robotic arm,

Robot automation production

How to Connect with Resources

Excellent quality, affordable price, exquisite technical strength

Blog Center

2022-06-01

Minghui will explain to you the working principle of the injection molding machine

Learn More +2022-06-01

What are the performance advantages of vertical injection molding machine?

In recent years, the global injection molding market has developed rapidly, and the industry has great potential for development.

2022-06-01

How does a vertical injection molding machine generally operate?

Usually consists of injection system, mold clamping system, hydraulic transmission system, electrical control system, lubrication system, heating and cooling system, safety monitoring system, etc.

2022-06-01

Minghui injection molding tells you what the classification of injection molding machines are

Vertical AC/DC injection molding machine series: This model is mainly used for the injection molding of connecting cables, various electronic, computer data cables and power plug cables.