Vertical two-platen injection molding machine

The vertical two-platen injection molding machine has many years of R&D and manufacturing experience, and is based on the market with stable and efficient performance. Clamping force: 200T~1500T Scope of application: ♦ This equipment is suitable for large products with inserts, and can be used in automobile, electronics, daily necessities, toys, tools and other industries

Category:

Two platen vertical injiction machine

Product Description

Vertical two-platen injection molding machine

Years of R&D and manufacturing experience, with stable and efficient performance based on the market.

Clamping force: 200T~1500T

Scope of application:

♦ This equipment is suitable for large-scale products with inserts, and can be used in automobile, electronics, daily necessities, toys, tools and other industries.

♦ Representative products: plastic flowers.

Features:

♦Professional computer for injection molding machine, high precision, self-diagnosis of fault computer, fault point is clear at a glance.

♦Using two-plate center hydraulic clamping, the clamping is stable and the force is even, making the clamping line of the product more beautiful.

♦Single slide design, safe and convenient operation, can be installed with automatic equipment to achieve full automation.

♦ The sliding plate adopts linear guide rail sliding structure, with precise position and smooth operation.

♦The main system adopts asynchronous servo energy-saving design; it has higher precision and faster response; it can save 50%~70% energy compared with ordinary non-energy-saving design products. 3. Advantages compared with traditional machines:

♦ The skateboard adopts a linear track sliding structure, without a skateboard base, saving space.

♦Clamping structure adopts cohesive nut locking structure, low work surface, simple installation, and can be directly operated without adding an operating table.

♦Unique clamping and high pressure structure, short high pressure time, about 0.3So

♦New structural design, lower oil temperature, and the fuel tank capacity is only 30% of the traditional machine.

♦ Large clamping stroke, more suitable for deep cavity injection molding.

♦It can be independently single-color injection molding, and can also be mixed with two-color injection molding.

|

|

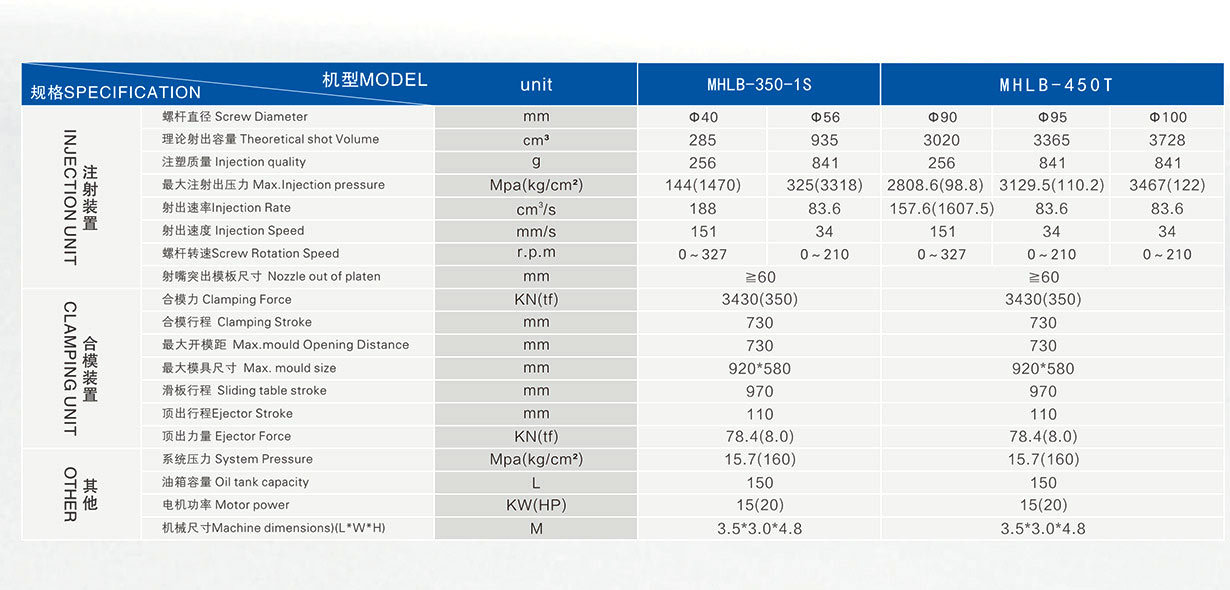

| MHLB-350T-1S 双板立式注塑机 | MHLB-450T四缸联动两板式注塑机 |

Related Products: